Scraper Blade Filters

Compositech manufactures scraper blades and doctor blades used for optimal drum filter and belt filter operations.

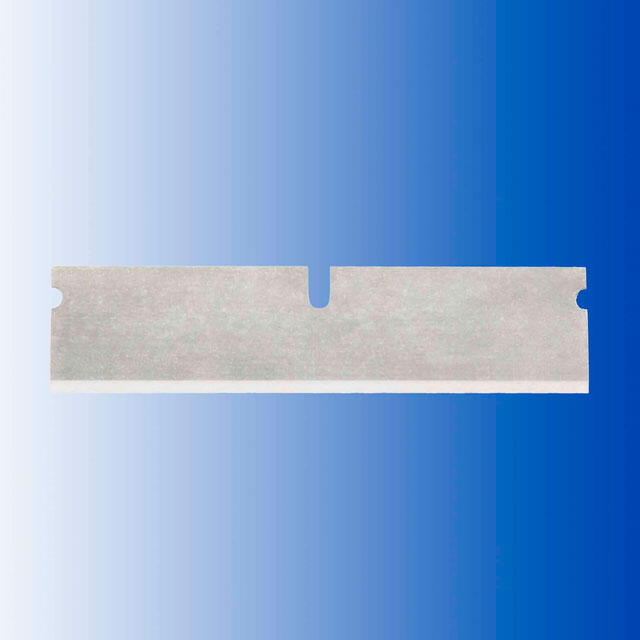

Scraper Blades

Precoat drum filters are designed to polish a solution by removing the fine particles suspended in the liquid. To provide this polish, the drum deck is coated with a filter medium that retains the fines and produces a clear filtrate. A small amount of filter aid medium is shaved off by a scraper blade each rotation to offer a clean surface for the next trip through the vat. For ideal operation, the scraper blade is designed to remove as little as 0.0004 inch of filter aid per revolution. At that rate, the drum rotates 2,500 times to remove one inch of precoat. This shaving of the filter aid is controlled by variable frequency drives and fine screws which carefully control the scraper blade.

Scraper Blade Manufacturer

Compositech's scraper blades are manufactured of the finest material and are available in a variety of lengths for the most efficient drum filter operations. Our blades are made from Stellite, a very hard cobalt based material known to maintain a sharp edge. We laser cut our scraper blades and sharpen them to a 23-degree angle. Since the filter medium is abrasive, the scraper blade edge must be kept sharp otherwise the cut is not smooth and vibrations to the discharge mechanism may be experienced. The fine edge on Compositech blades increases the blade life and reduces chatter.

In an effort to reduce the number of blades required for a drum filter, Compositech manufactures standard 6 inch blades as well as longer lengths including 12 inch, 18 inch, 24 inch, and 48 inch scraper blades. Longer blades and fewer joints result in extended blade life for the filter. Additionally, our longer scraper blades are more easily installed and aligned, translating to a reduction in filter downtime.

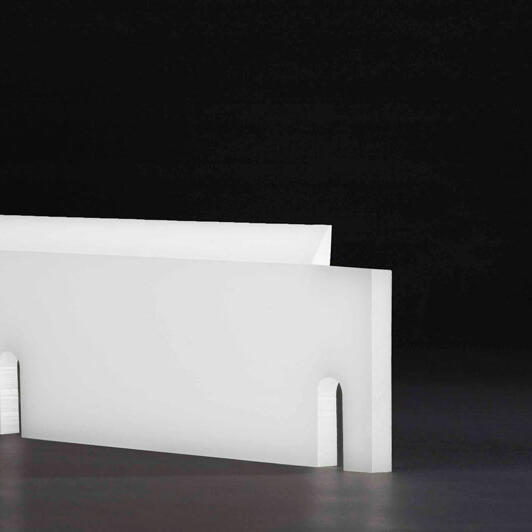

Doctor Blade Manufacturer

A belt filter doctor blade scrapes off as much sludge as possible from the dewatering belt without causing damage to the belt or seam. The doctor blade rides on the belt surface in front of the wash box where final belt cleaning occurs. By removing the maximum amount of sludge before the belt is washed, the doctor blade ensures optimal performance of the washing system resulting in a longer lasting, better functioning belt.

At Compositech we take performance factors into account in designing our doctor blades and in using a high speed router to cut our blade bevels with precision. This method produces an efficient doctor blade, far superior to other blades which are typically cut by a table saw and have a rough, uneven surface. Compositech doctor blades come in many variations to meet our customer’s specific needs. We make both single bevel and dual bevel doctor blades and we make the blades with slots and pre-drilled holes as needed. Compositech's doctor blades are manufactured of the finest materials available including UHMW, UWHME-PE, HDPE, and Tivar 88 depending on our customer’s specific needs.

Compositech supplies replacement parts for Ametek, Andritz, Ashbrook, Dorr-Oliver®, Eimco®, Enviroquip, Komline-Sanderson, Parkson, Sernagiotto, Sernatech, Siemens, US Filter, Westech and most other brands of filtration equipment.

Click here to submit a Request for Quote

or call us today at 281-648-3557